Hydraulic systems power everything from heavy machinery to automotive transmissions, and they are the lifeblood of many industrial and mobile applications. Because these systems rely on the effective circulation of hydraulic fluid to fulfill numerous duties, their correct operation is critical. One often overlooked but crucial component of hydraulic systems is the hydraulic filter. In this article, we will explore the importance of hydraulic filters in maintaining the health and longevity of hydraulic systems.

Contaminant Removal

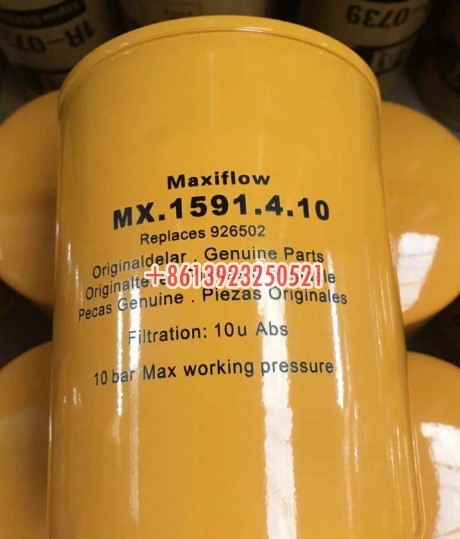

Hydraulic systems are vulnerable to contamination from various sources, such as dust, debris, metal particles, and even water. These contaminants can significantly compromise the efficiency and reliability of hydraulic systems. Hydraulic filters serve as the first line of defense against harmful contaminants, capturing them before they enter the system.

Allowing dust and dirt particles into the system can induce abrasive wear on hydraulic components, resulting in premature failure. Metal particles, on the other hand, can accumulate as a result of component wear and tear and cause a chain reaction of harm as they circulate through the system. Hydraulic filters effectively remove these contaminants, preventing damage and downtime.

Improved System Performance

Clean hydraulic fluid is essential for maintaining optimal system performance. When contaminants are present, they can interfere with the fluid's ability to transmit pressure and perform its intended functions. A clogged or filthy filter reduces hydraulic fluid flow, resulting in lower efficiency, slow operation, and overall system performance.

Regularly replacing or cleaning hydraulic filters ensures that the fluid remains clean and flows smoothly. This, in turn, helps maintain the system's efficiency, responsiveness, and overall productivity. Consistent performance is critical for businesses that rely on accurate and reliable hydraulic systems, such as manufacturing and construction.

Extended Component Life

Hydraulic filters not only protect the hydraulic fluid but also safeguard the longevity of system components. Contaminants in the system can hasten the wear and tear on components such as pumps, valves, cylinders, and seals. This might result in costly repairs and replacements over time.

Hydraulic filters assist in extending the life of these crucial components by properly eliminating impurities. This results in reduced maintenance costs and fewer unexpected breakdowns, contributing to overall cost savings and increased equipment uptime.

Enhanced Reliability

Hydraulic systems are often employed in mission-critical applications, where even a minor malfunction can lead to significant consequences. Contaminants in hydraulic fluid can cause system failures and unscheduled downtime, resulting in production delays and safety issues.

By maintaining a consistent degree of cleanliness in the hydraulic fluid, reliable hydraulic filters play an important role in preventing these concerns. This enhanced reliability ensures that hydraulic systems perform consistently, reducing the risk of unexpected failures and the associated costs and safety concerns.

Environmental Responsibility

Hydraulic filters contribute to environmental responsibility in addition to ensuring the performance and lifespan of hydraulic systems. If not correctly managed, contaminated hydraulic fluid can result in hazardous waste and environmental hazards. By removing contaminants at the source, hydraulic filters help reduce the environmental impact of hydraulic systems, aligning with sustainability goals.

Conclusion

Hydraulic filters are an often-underappreciated component of hydraulic systems, but their importance cannot be overstated. They are critical in maintaining system performance, safeguarding components, and assuring hydraulic system dependability and lifetime. As one of the trusted filter suppliers, COOBELL offers a wide range of car filters including hydraulic filters. Click the link for more product details now!

.jpg)

.jpg)